Tyvek® vs. Typar®

Article

Tyvek® Water-Resistive Barriers (WRBs) provide superior performance and durability

DuPont™ Tyvek® Water-Resistive Barriers (WRBs) give you the durability and performance needed to build more comfortable and energy-efficient homes. Trusted by quality building professionals everywhere, DuPont™ Tyvek® Water-Resistive Barriers, part of the complete DuPont Weatherization Systems offering, deliver superior performance compared to Typar® and film laminate or coated WRBs as further described in this document.

CHOOSING THE RIGHT WRB

The primary purpose of a house wrap is to prevent air penetration and water damage in the wall assemblies of the homes you build. A good WRB must perform four equally important functions:

1. It MUST function as an air barrier to help prevent drafts.

2. It MUST provide bulk water resistance to help prevent water that gets behind the exterior cladding from entering into the wall cavity.

3. It MUST offer moderate-to-high vapor permeability to allow any water that does enter the wall cavity to evaporate.

4. It MUST be durable enough to withstand job-site challenges during installation.

In order to accomplish all of this, a product needs to provide the proper balance of air and water resistance and vapor permeability, and also be strong enough to withstand the rigors of the construction process and perform after installation.

Tyvek® and Typar® in 8X Magnification after 1 abrasion cycle

Tyvek® and Typar® in 75X and 200X Magnification after 1 abrasion cycle

Test Result of Tyvek® and Typar® for air and water resistance and drying behavior after abrasion exposure

DUPONT™ TYVEK® HOMEWRAP® – ENGINEERED FOR SUPERIOR PERFORMANCE

DuPont created Tyvek® HomeWrap® to have the optimum balance of properties for superior performance against the elements AND the competition. Simply put, Tyvek® outperforms Typar® house wrap due to a fundamental difference in the way the Tyvek® WRBs are made.

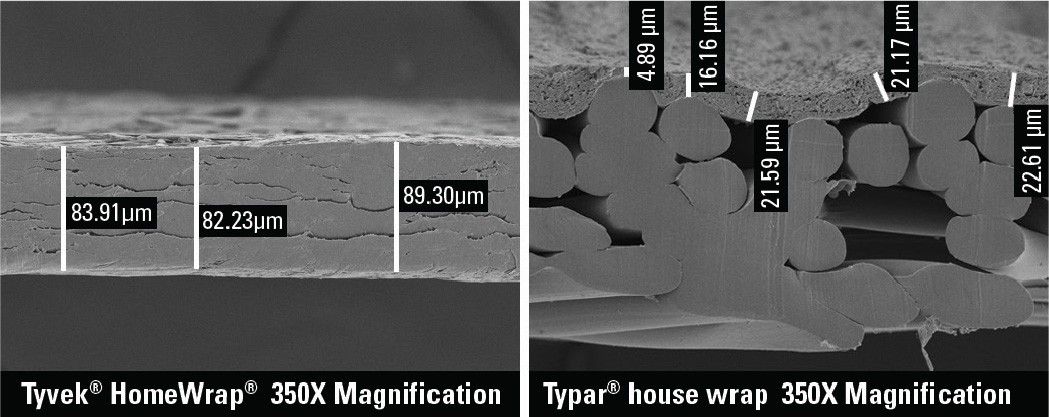

Tyvek® HomeWrap® is a uniquely engineered product made by spinning extremely fine high–density polyethylene (HDPE) fibers that are fused together to form an extremely tough and uniform structure which is continuous throughout the WRB. The fiber structure creates microscopic pores that resist bulk water and air penetration, while allowing moisture vapor to pass through. The performance of DuPont™ Tyvek® HomeWrap® exceeds the International Building Code and the International Residential Code requirements as a water-resistive barrier and meets the air barrier requirements of ICC-ES AC-38 and the ASTM E1677 Standard Specification for a Type I air barrier.

Typar® products are comprised of a thin film coating on a polypropylene fiber mesh. The polypropylene backing consists of a coarse mesh, similar to that of a landscape fabric, which is necessary to provide support for the thin film layer. This mesh is tear resistant but offers no protection for water and air penetration. The thin coating or functional layer is added so minimum water and air resistance standards are met.

Also, as you can see in the electron micrograph image of Typar®, the thickness of the functional layer is not a

consistent depth. In this particular example, the thickness varied from 4.8 to 22.6 microns – which is less than half the thickness of a human hair. The thinnest areas tend to occur above the protruding fibers, making these areas even more susceptible to damage.

By comparison, the entire thickness of Tyvek® HomeWrap® functions as an air barrier and provides water resistance

and is 4 to 20 times the thickness of the functional layer of Typar® depending on the point at which the functional layer of Typar® is measured.

Click to download the whitepaper to see the difference between Tyvek® andTypar® in details, in terms of DURABILITY, ABRASION RESISTANCE and VAPOR PERMEABILITY.

Conclusion

DuPont has the technology to engineer each WRB property of Tyvek® HomeWrap® for optimum performance. As a result, Tyvek® HomeWrap® offers high vapor permeability without sacrificing resistance to air and bulk water penetration. Also, the functionality of the entire thickness ensures the product will perform after exposure to the rigors of the jobsite and installation. Typar®, on the other hand, relies on a thin functional layer which is susceptible to damage that can limit the products performance as an effective WRB. Once again, Tyvek® HomeWrap® offers the best balance of properties to help you build more durable, energy efficient structures